Accurate early warning with zero misjudgment; Zhongyun Monitoring helps food companies eliminate equipment failure risks in advance

Release time:2025-08-01

Precise Fault Isolation: From Data Anomaly to On-site Verification

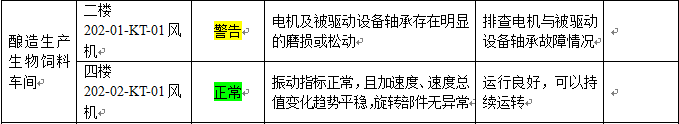

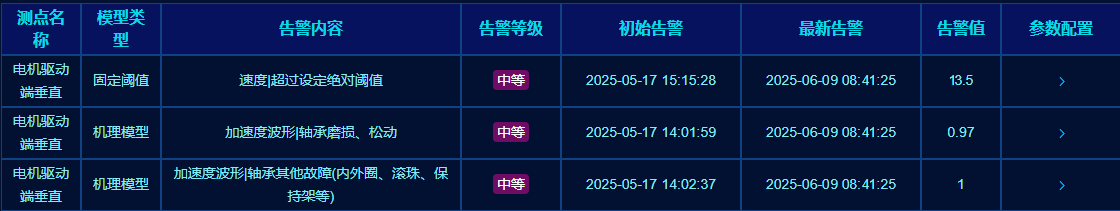

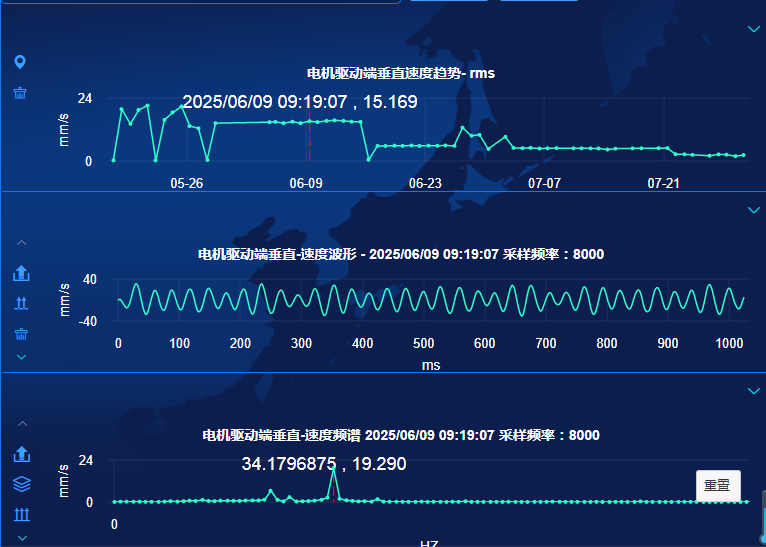

2025 Year 6 Early Month In early , a key fan device (equipment number: second floor) at a food factory in Hubei Province 202-01-KT-01) After starting operation anomaly occurred, and the vertical measurement point speed value of the motor drive end exceeded the normal range (≤ 5mm/s ) and rose to 13.5mm/s and remained high. Wuhan Zhongyun Industrial Equipment Online Monitoring System detected a continuous increase in the vibration data of this equipment in real time. The vibration trend, waveform, and spectral characteristics all showed typical bearing wear or looseness faults, triggering threshold alarms and mechanism diagnosis alarms on the software platform. Zhongyun diagnostic engineers clearly pointed out the fault risk and provided maintenance suggestions in the equipment analysis report of that month. The company's deployed intelligent equipment monitoring system, which had only been online for just over two months, captured multiple signs of equipment degradation through the intelligent diagnostic platform combined with "expert care" services.

Figure 1 Diagnostic Report Alarm and Maintenance Suggestions

Figure 2 Online Monitoring System Alarm

Rapid Response Closed Loop: From Work Order Issuance to Fault Confirmation

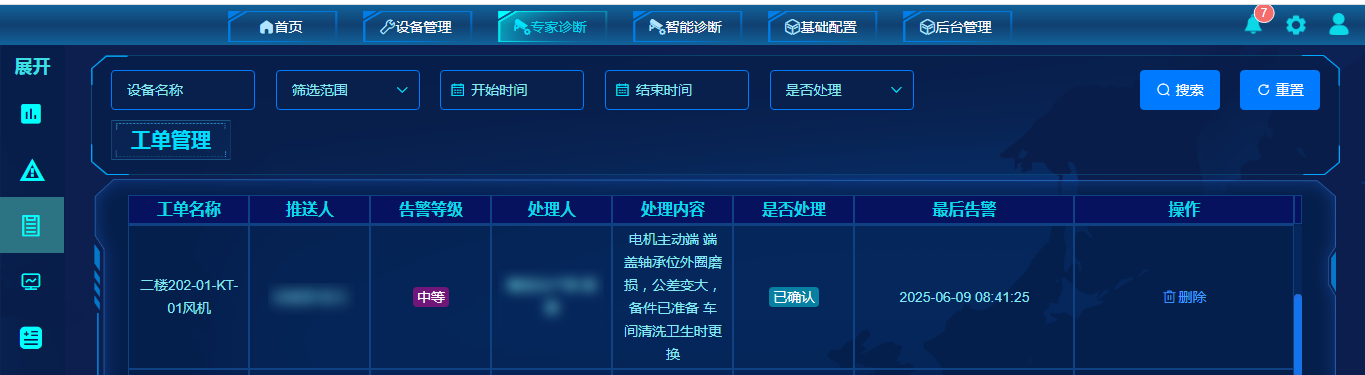

After receiving the system's automatically pushed alarm information, the enterprise's equipment maintenance team generated a system maintenance work order on June 9 and issued it to the production workshop. The maintenance engineer disassembled and inspected the equipment and found obvious wear marks on the motor bearing and an increase in the tolerance, which completely matched the fault conclusion provided by Zhongyun Technology. On-site confirmation showed that if such hidden dangers were not dealt with in time, it would lead to bearing seizure, damage to transmission components, and other chain reactions, ultimately leading to unplanned downtime of the production line.

Figure 3 Alarm Confirmation

Figure 4 Confirming the equipment status with the factory and handling it promptly

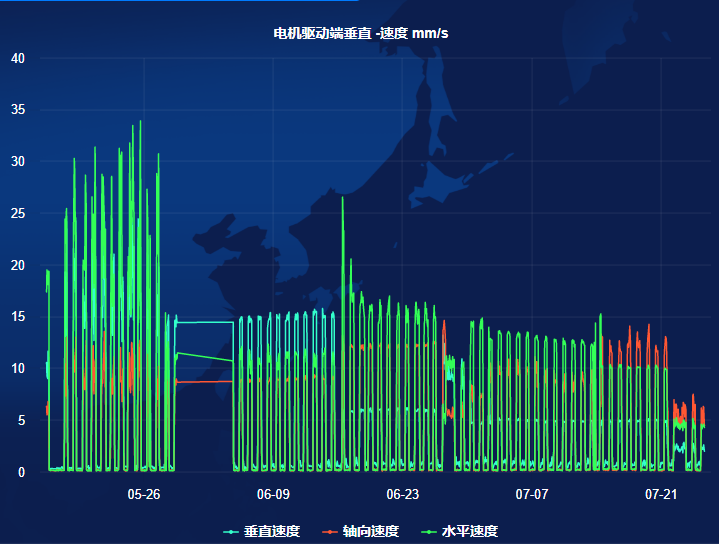

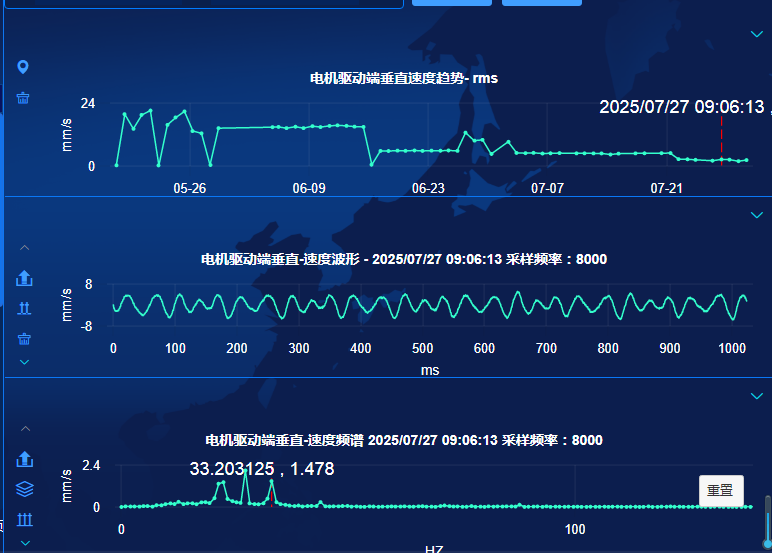

After confirming the alarm, the factory immediately repaired and replaced the bearing. After the repair, the motor measurement point speed characteristic value dropped to 4.8mm/s , returning to the normal range, and the waveform peak value decreased significantly.

Figure 5 Trend of Equipment Motor Measurement Point Speed Value (Before and After Repair)

Figure 6 Waveform and Spectrum of Equipment Speed Before Repair

Figure 7 Waveform and Spectrum of Equipment Speed After Repair

Cost Reduction and Efficiency Improvement Results: Making Implicit Costs Explicit

This intelligent monitoring system achieves precise early warning of faults by analyzing vibration spectra, temperature trends, and mechanism models, leaving sufficient time for repairs and effectively ensuring production continuity, avoiding production losses and high implicit costs caused by sudden shutdowns. Its "AI diagnosis + engineer review" model ensures a low false alarm rate. Early intervention significantly reduces repair costs and reduces unnecessary disassembly and inspection by more than 60% in the long term, extending equipment life by more than 30%, and comprehensively reducing maintenance costs by more than 40%.

Previous page

Related news

Make industry smarter and equipment healthier

Service Hotline

+86-27-6349 9950

Contact Information

Email: administrator@hbicc.com

Address: No. 6, Fozulingle Third Road, East Lake High-tech Development Zone, Wuhan, Hubei Province