Diagnostic algorithm software

Category:

Possesses the industry's most extensive library of diagnostic algorithm models. Through in-depth cooperation with renowned university laboratories, and by closely combining theoretical research with on-site engineering data, we have successfully developed over 100 precision diagnostic algorithm models targeting component levels, capable of covering more than 90% of fault modes in industrial equipment.

Contact:

Algorithm Introduction

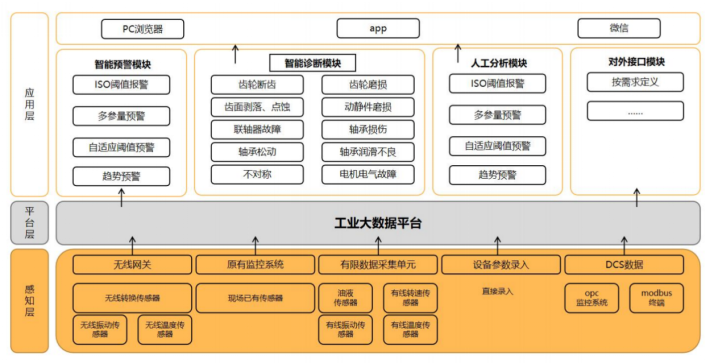

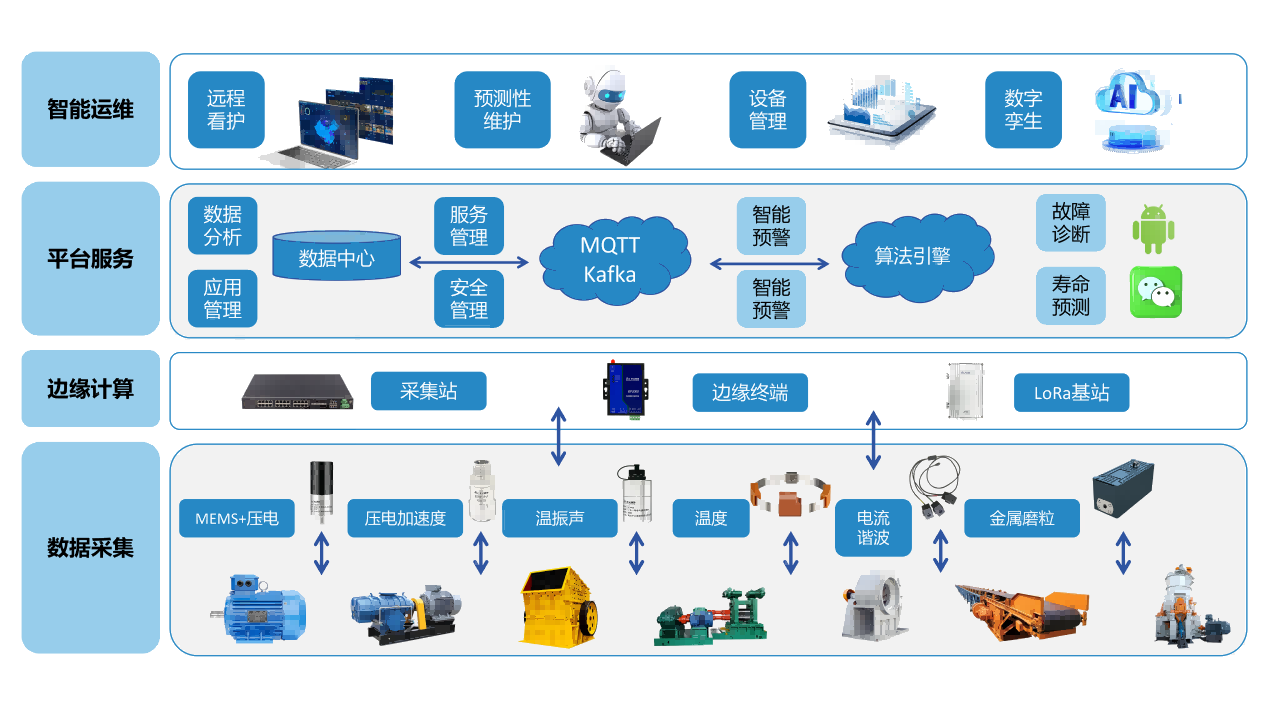

To meet the demands of modern industrial internet, the diagnostic algorithm software adopts a microservice architecture design. This not only facilitates easy integration into various application environments but also seamlessly integrates with the IEPLAT intelligent equipment maintenance platform, providing users with a highly efficient and intelligent equipment maintenance solution.

Algorithm Characteristics

Wide Applicability: The algorithm covers a wide range of industrial equipment, from simple to complex, adapting to the needs of different industries. High-Precision Diagnostics: Combining traditional signal processing with modern deep learning technology ensures comprehensive monitoring and accurate prediction of equipment status. Intelligent Early Warning: Multiple early warning mechanisms, including fixed thresholds, dynamic thresholds, and trend prediction, are used to detect potential problems in advance. Easy Integration: The microservice architecture design allows the software to be easily integrated into various application environments, and it has been seamlessly integrated with the IEPlat equipment intelligent operation and maintenance platform.

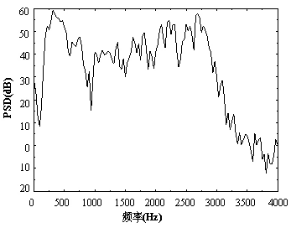

Power Spectral Density: Used for frequency domain analysis, it helps identify periodic components in vibration signals, which is particularly useful for rotating machinery.

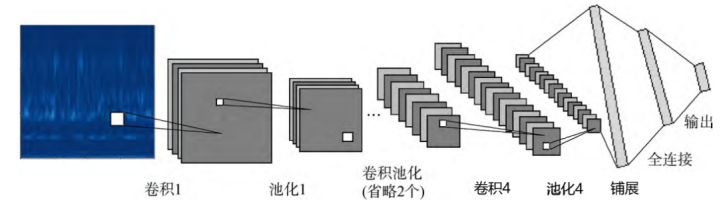

Wavelet Transform combined with Deep Convolutional Neural Network (CNN): This combines the advantages of traditional signal processing methods and modern deep learning, enabling effective feature extraction and automatic learning of complex patterns.

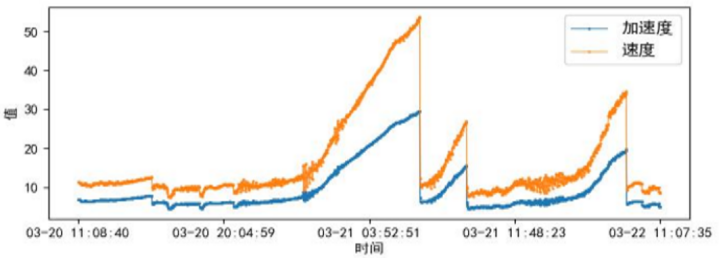

Fixed Threshold Warning: Suitable for monitoring parameters under known stable states, issuing an alert when equipment operating parameters exceed the preset safety range.

System Architecture

Rotating Machinery Equipment: Monitors the health status of motors, pumps, fans, compressors, and turbines to predict potential failures by analyzing signals such as vibration, temperature, current, pressure, flow rate, and exhaust temperature.

Transmission System: Evaluates wear or imbalance issues in gearboxes, couplings, and belt drives using characteristics such as gear mesh frequency, sideband energy, alignment, and tightness.

Hydraulic and Pneumatic Systems: Monitors oil quality, leaks, pressure fluctuations, sealing, response time, and positional accuracy to ensure stable operation of hydraulic pumps and cylinders and to promptly detect anomalies.

Electrical System: Maintains the safety and reliability of power transformers, circuit breakers, and cables by detecting parameters such as partial discharge, oil temperature, winding resistance, number of operations, degree of contact wear, and insulation resistance.

Thermal System: Tracks water level, steam pressure, combustion efficiency, heat transfer efficiency, scaling, and leakage risks to ensure the effective operation and energy efficiency optimization of boilers and heat exchangers.

Material Download

Recommended products

Leave a message

We will contact you as soon as we receive your information and give you a surprise.

Service Hotline

+86 27-6349 9950

Contact Information

Email: administrator@hbicc.com

Address: No. 6, Fozulingle Third Road, East Lake High-tech Development Zone, Wuhan, Hubei Province