Case Study of Cement Plant Roller Press Gearbox Failure

Release time:2025-08-27

Gear Reducer Overview

Certain JGXZ Type gear reducer, vibration at the high-speed shaft drive end shows an increasing trend, bearing temperature 66 ℃ , working load unchanged, motor speed and oil supply pressure are normal.

Motor speed is 1488rpm , power frequency 24.8Hz Gear parameters of the high-speed stage of the reducer are shown in Table 1:

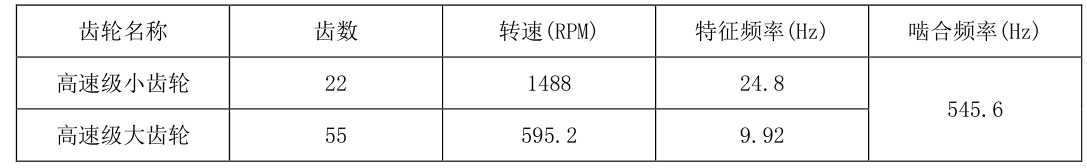

Table 1 Gear parameters of the high-speed stage of the reducer

At the high-speed shaft drive end, the monitored vibration signal severity value is 15.9mm/s , and at the non-drive end is 13.8mm/s , both values are relatively high, and the drive end exceeds the alarm value. 。 Characteristic frequencies of the high-speed stage bearing are shown in Table 2:

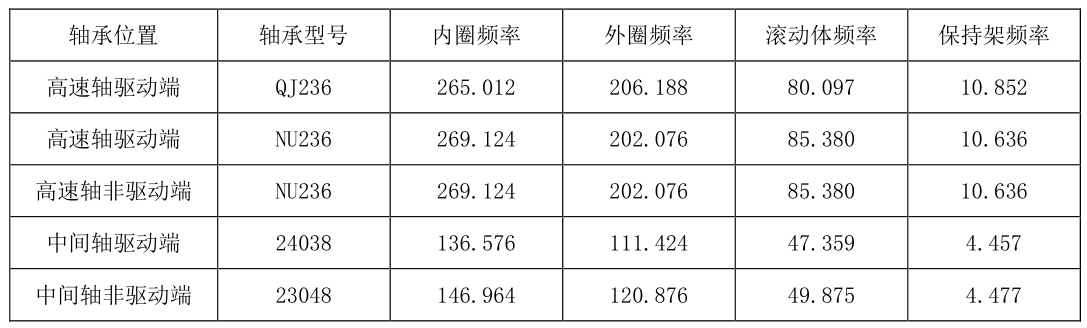

Table 2 Characteristic frequencies of the high-speed stage bearing of the reducer (unit: Hz )

Fault Analysis

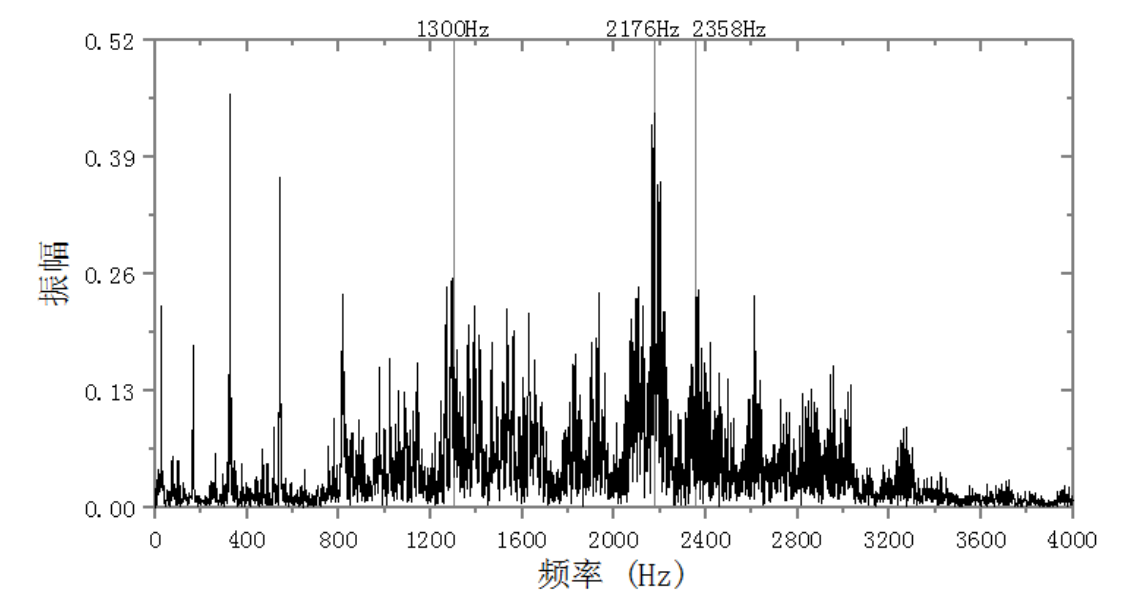

In the Fourier spectrum chart in Figure 1 it is found that, below 1000Hz some sideband components are fewer. Combined with Tables 1 and 2 it can be seen that, in the spectrum 1000Hz the parts below are all gear meshing frequencies, and the sidebands are not obvious. It can be preliminarily judged that the abnormal vibration is not caused by gear faults. However, near frequencies such as 1300Hz、 2176Hz 、2358Hz there are more sideband components, and these frequencies are not multiples of the gear meshing frequency. The bearing temperature has reached the alarm value, so these sidebands can be considered caused by bearing faults. However, due to the complexity of the sideband components, fault analysis is inconvenient, and envelope spectrum analysis of the vibration signal should be performed (Figure 2 ).

Figure 1 Fourier spectrum chart

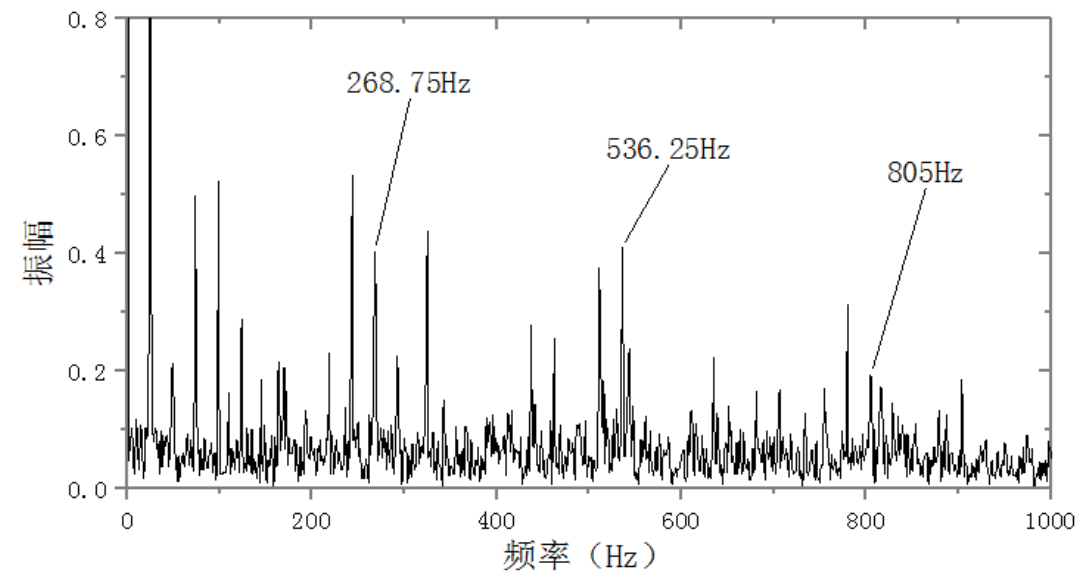

Figure 2 Envelope spectrum chart

In the envelope spectrum, frequency components of 268.75Hz and their multiples exist, close to the bearing NU23 inner ring fault frequency, it can be inferred that NU236 type bearing has a fault, and it can be inferred that the fault is in the bearing inner ring.

Since there are bearings at both ends of the high-speed shaft NU236 , the vibration signal severity values at both ends can be compared. The larger the value, the stronger the vibration signal. Since the vibration signal severity value at the drive end is greater, it can be inferred that the bearing fault is at the high-speed shaft drive end.

Conclusion and Suggestions

Conclusion: Bearing at the high-speed shaft drive end of the reducer NU236 has a fault (bearing inner ring fault). Due to the drive end bearing fault, the non-drive end bearing is unevenly loaded, which may cause slight local wear of components in the non-drive end bearing.

Suggestion: Closely monitor the vibration trend of the reducer and inspect the bearing for faults at an appropriate time to stop the machine. NU236 It is recommended to replace the bearings at both ends of the high-speed shaft simultaneously. NU236。

Fault Verification

After stopping the equipment for inspection and disassembling the reducer, the drive end bearing was disassembled, and peeling was found on the surface of the bearing inner ring, as shown in Figure 3 , verifying the fault analysis conclusion.

Figure 3 Bearing Disassembly Diagram

Related news

Make industry smarter and equipment healthier

Service Hotline

+86-27-6349 9950

Contact Information

Email: administrator@hbicc.com

Address: No. 6, Fozulingle Third Road, East Lake High-tech Development Zone, Wuhan, Hubei Province