Operations and Maintenance Management Platform

Category:

Embracing the Industry 4.0 Era: IEPlat Tengyun – the Intelligent Operations & Maintenance Platform, empowering comprehensive lifecycle management of equipment. By integrating cutting-edge sensing technologies, advanced data analytics, and AI algorithms, the platform delivers real-time equipment monitoring, predictive fault detection, and intelligent maintenance solutions. This approach maximizes equipment availability, significantly reduces maintenance costs, and ultimately helps businesses unlock greater value. Leveraging equipment operational data, the system accurately predicts potential failures and enables proactive interventions before issues arise, preventing unplanned downtime and minimizing production losses.

Contact:

Design characteristics

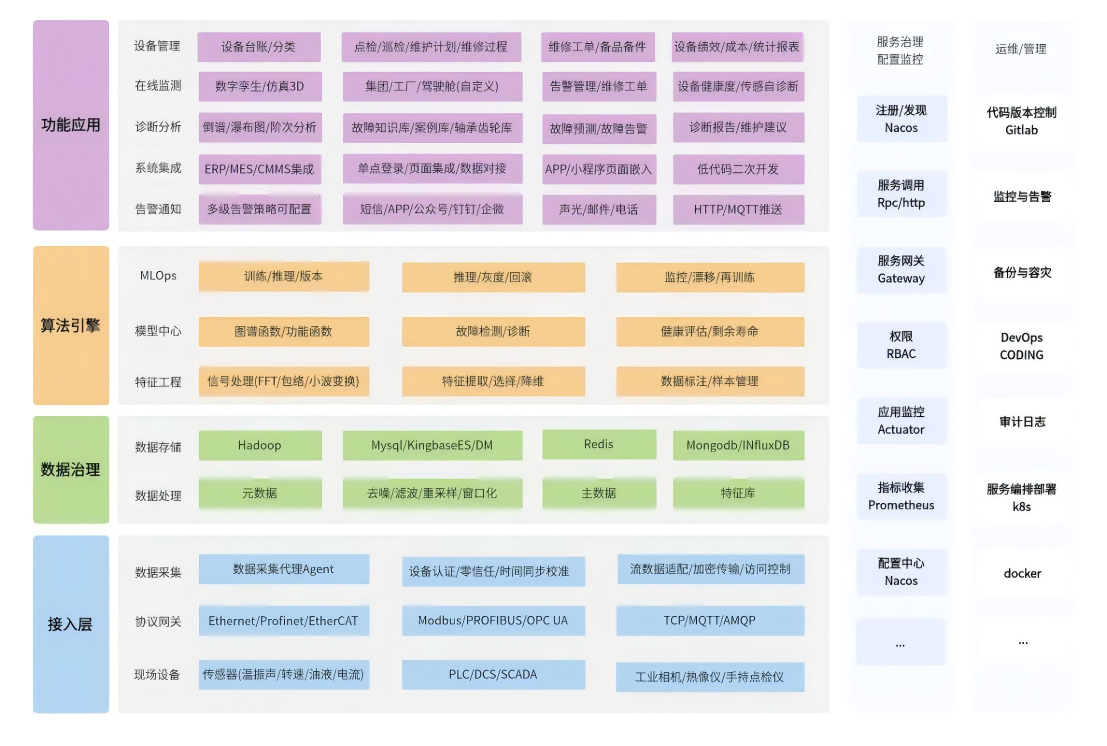

The IE-Plat Tengyun Intelligent Operations and Maintenance Platform uniquely integrates advanced PHM predictive maintenance technology with a comprehensive equipment lifecycle management system, breaking down data silos and business fragmentation that have long plagued traditional equipment management. This creates an intelligent management ecosystem covering the entire lifecycle of equipment—from "selection and procurement" to "installation, operation, maintenance, and eventual retirement." Not only does it enable real-time monitoring of equipment conditions, predict potential failures, and deliver smart maintenance solutions, providing equipment with round-the-clock "health check-ups" and "failure predictions," but it also serves as a decision-making system that continuously optimizes asset value throughout the equipment's entire lifespan.

1. End-to-End Data Integration Across the Entire Lifecycle

The platform establishes a unique "digital DNA" profile for each device. From procurement contracts and installation records to operational parameters, maintenance history, and even health status alerts, all data is seamlessly integrated. The PHM system continuously captures real-time operational conditions, performance degradation trends, and predictive fault data—data that is then fed back to empower decision-making at every stage of the equipment lifecycle: from initial selection during the pre-lifecycle phase, to optimizing maintenance strategies in the mid-life period, and even informing end-of-life assessments such as scrapping or replacement. This approach enables a fully data-driven, closed-loop management system across the entire lifecycle.

2. Full-Process Business Collaboration Optimization

Fault diagnosis alerts and outcomes are no longer isolated pieces of information—they have become critical commands that automatically trigger relevant business processes within the system. Based on predicted failure times, component-specific issues, and remaining useful life (RUL), the system can automatically generate optimal maintenance work orders, precisely initiate spare parts procurement workflows, and optimize scheduling plans for maintenance personnel. This effectively transforms the "prophetic" capability of predictive maintenance into proactive actions that drive cost reduction and efficiency gains.

Platform Features

Supports multiple industrial protocols and data interfaces, seamlessly integrating with existing IT/OT systems. It is compatible with multi-source heterogeneous data, effortlessly combining time-series data, vibration, temperature, pressure, current, oil fluid, and other sensor data types.

Visualized Panoramic Monitoring

One-stop overview of the real-time health status of all equipment, enabling quick identification of abnormal devices. Drill down step by step—from the factory and production line to individual equipment—and visually present historical data, real-time trends, spectrum analysis charts, and more. Integrated with digital twin models, this solution achieves precise 3D visualization and localization of fault locations.

A flexible and configurable early warning system

Supports multi-level alarm threshold customization (Normal, Medium, Severe). Offers multiple alert methods (in-station messages, email, SMS, WeChat, phone calls, audio-visual alerts) to ensure critical information reaches the responsible parties promptly.

Powerful integration and scalability

Offers a rich set of RESTful APIs, enabling seamless integration with third-party systems such as ERP, MES, CMMS, EAM, and more, automatically triggering maintenance work orders. The individual functional modules are decoupled, allowing for flexible combination and scalable expansion based on customer needs, while supporting public cloud, private cloud, and hybrid deployment options.

Comprehensive Value Decision Support

Deep integration has ushered in an unprecedented level of decision-making sophistication. Managers can now not only answer questions like "When will this equipment fail?" but also address more strategic, lifecycle-oriented queries: "Which equipment brands and models are most reliable? (Optimizing procurement)," "What’s the return on investment for our current maintenance strategies? (Optimizing strategies)," and "When is the most cost-effective time to upgrade or replace equipment? (Optimizing upgrades)." This shift enables a transformative leap—from managing individual equipment health to maximizing the overall return on investment (ROI) of your entire asset portfolio. Through this deep integration, we’re redefining equipment management: it’s no longer just a cost center, but a vital hub for driving value creation. The platform ensures that every piece of equipment remains in peak condition throughout its entire lifecycle—delivering optimal performance at the lowest total cost of ownership (TCO), while unlocking maximum productivity potential.

Algorithm Engine

The algorithm engine is the platform's "intelligent brain," transforming cutting-edge algorithms into simple, user-friendly system functionalities. This allows you to effortlessly harness expert-level equipment prediction and health management capabilities—without needing to delve into complex models yourself. At the core of its predictive diagnostics, graph analysis, and intelligent decision-making are powerful, integrated smart algorithms that deliver seamless, end-to-end solutions. Moreover, this engine serves as a highly integrated, fully functional, and standardized algorithmic service hub, providing "ready-to-use" professional analytical capabilities for advanced applications above it.

Signal Preprocessing and Feature Extraction Center

It provides a rich library of standardized functions that automatically perform pre-processing tasks such as data cleaning, noise reduction, filtering, and normalization on multi-source, heterogeneous raw data (e.g., vibration, current, temperature, acoustics, etc.). Built-in algorithms enable the automatic extraction of dozens of time-domain, frequency-domain, and time-frequency-domain features—such as amplitude, mean, variance, kurtosis, FFT spectra, and wavelet packet energy—providing high-quality, standardized input feature vectors for subsequent diagnostic models.

Diagnostic Model and Atlas Generator

The core computing unit of the engine integrates all advanced diagnostic algorithms. This module provides all diagnostic functions, including fault identification, health assessment, trend prediction, and Remaining Useful Life (RUL) calculation, among others.

Data Management and Model Training Center

Provides a visualized model training and hyperparameter tuning system, supporting data annotation, feature selection, model training, validation, and one-click deployment. Through the closed-loop process of "Data-Diagnosis-Decision-Feedback," it automatically collects operations and maintenance feedback data, continuously optimizing model performance to enable algorithms to self-learn and evolve over time.

Real-time Scheduling and Business Orchestrator

As the "nervous system" of the engine, it handles the dynamic hot-plug loading and collaborative scheduling of all algorithmic modules. Based on a pre-defined, complex business topology, it invokes the corresponding preprocessing, feature-extraction, or diagnostic models with millisecond-level response speeds.

Material Download

Recommended products

Leave a message

We will contact you as soon as we receive your information and give you a surprise.

Service Hotline

+86 27-6349 9950

Contact Information

Email: administrator@hbicc.com

Address: No. 6, Fozulingle Third Road, East Lake High-tech Development Zone, Wuhan, Hubei Province