Operations Management Platform

Category:

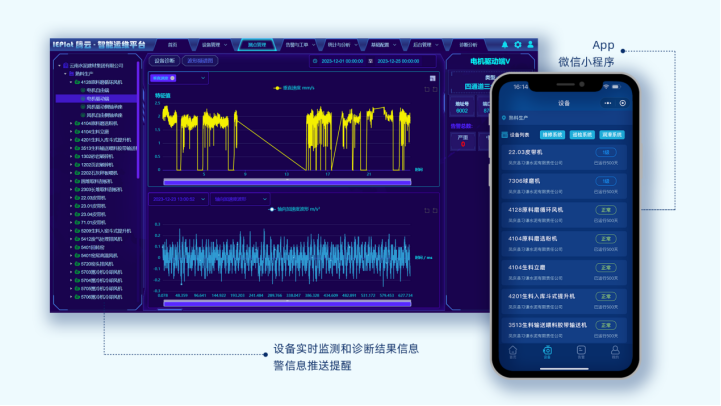

Embracing Industry 4.0: IEPlat Tengyun - Intelligent Operation and Maintenance Platform, empowering the entire lifecycle management of equipment. Through the integration of advanced sensing technology, data analysis, and artificial intelligence algorithms, it achieves real-time monitoring of equipment status, fault prediction, and intelligent maintenance, maximizing equipment availability, reducing maintenance costs, and creating greater value for enterprises. Based on equipment operation data, it predicts potential failures and intervenes before they occur, thus avoiding unexpected downtime and production losses.

Contact:

Design characteristics

Core Functions

Real-time Status Monitoring: Collects real-time operating parameters of the equipment, such as temperature, vibration, pressure, and current, through various sensors deployed on the equipment. Data Analysis and Diagnosis: Analyzes and processes the collected data using big data analysis, machine learning, and artificial intelligence algorithms to identify abnormalities and potential faults in the equipment's operating status. Fault Prediction and Warning: Predicts potential future equipment failures based on historical data and current status, and issues early warnings to provide maintenance personnel with sufficient preparation time. Intelligent Maintenance Decision-Making: Provides optimal maintenance strategy recommendations based on fault prediction results, including maintenance time, content, and required spare parts, helping enterprises achieve lean maintenance.

Maintenance Services

Efficient customer relationship management is key to the successful application of the PHM system. Therefore, the PHM system deeply integrates a powerful CRM (Customer Relationship Management) system to provide customers with comprehensive and high-quality services: Efficient Management of Customer Information: The CRM system centrally stores and manages customer basic information, equipment information, maintenance records, contract information, etc., achieving a unified view of customer data and facilitating maintenance personnel's quick understanding of customer needs and equipment status. Customer Service Optimization: Through the CRM system, customers can easily submit service requests, check maintenance progress, and provide service quality feedback. Maintenance personnel can respond promptly to customer needs, provide personalized service solutions, and improve customer satisfaction. Service Tracking and Analysis: The CRM system records each service process and generates detailed reports to help enterprises analyze service efficiency, customer satisfaction, and other indicators, continuously improving service quality. Proactive Care and Maintenance: Based on the customer's equipment operation data and maintenance records, the CRM system can proactively remind customers to perform maintenance, provide professional consultation and support, and establish long-term cooperative relationships.

Full Lifecycle Management

IEPlat Tengyun - Intelligent Operation and Maintenance Platform not only focuses on the operation and maintenance phase of equipment, but also focuses on the full life cycle management of equipment, providing comprehensive solutions from equipment procurement, installation and commissioning, operation and maintenance to disposal: Procurement Phase: Provides equipment selection recommendations, recommending the most suitable equipment models and configurations based on customer's actual needs and application scenarios. Installation and Commissioning Phase: Provides professional installation guidance and commissioning services to ensure that the equipment can operate safely and stably. The operation and maintenance management platform records the installation and commissioning process to form equipment files. Operation and Maintenance Phase: Maximizes equipment availability and operating efficiency through real-time monitoring, fault prediction, and intelligent maintenance decision-making. The operation and maintenance management platform provides functions such as visualized display of equipment operating status, fault warning, and maintenance work order management. Disposal Phase: Provides professional disposal recommendations, including equipment dismantling, recycling, and environmental protection treatment, to minimize environmental impact. The operation and maintenance management platform records equipment disposal information to complete the closed-loop management of the equipment life cycle.

Platform Features

Core Values

The system is equipped with a powerful operation and maintenance management platform, providing strong support for the entire life cycle management of equipment:

Unified monitoring and management: The platform centrally monitors the operating status of all equipment, providing a unified management interface to facilitate maintenance personnel in quickly understanding the equipment status. Visual display: The operation data and health status of the equipment are intuitively displayed through various methods such as charts, curves, and maps. Intelligent alarms: The system automatically issues alarm information based on preset thresholds and algorithms, reminding maintenance personnel to handle abnormal situations in a timely manner. Work order management: Supports the creation, allocation, execution, and tracking of maintenance work orders to improve maintenance efficiency. Report analysis: Provides a wealth of reports and analysis tools to help enterprises analyze equipment operating conditions, maintenance costs, and efficiency indicators. Mobile application: Provides a mobile application to facilitate maintenance personnel to monitor equipment status and handle maintenance tasks anytime, anywhere.

Usage Effectiveness

Higher equipment availability: Reduce unexpected downtime and improve production efficiency.

Lower maintenance costs: Avoid excessive maintenance and emergency repairs, reducing maintenance costs.

Longer equipment life: Extend the service life of equipment through timely maintenance and upkeep.

Better customer service: Provide comprehensive customer support to improve customer satisfaction.

More intelligent decision support: Data-driven decision-making to achieve lean management.

Material Download

Recommended products

Leave a message

We will contact you as soon as we receive your information and give you a surprise.

Service Hotline

+86 27-6349 9950

Contact Information

Email: administrator@hbicc.com

Address: No. 6, Fozulingle Third Road, East Lake High-tech Development Zone, Wuhan, Hubei Province